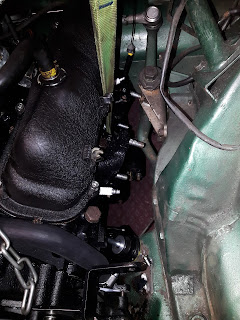

The heater valve is fitted under the alternator and is also used to change the hose diameter from 19mm out of the thermostat housing to 15mm used in the rest of the circuit.

Heater fan needs to be wired into circuit.

Heater fan needs to be wired into circuit.Radiator fitted - top hose is the standard Granada item shortened a little.

Bottom hose is from a standard Capri.

The thermostat housing outlet points forward and the radiator inlet (outlet?) is also pointing forwards inline.

The Capri hose is reversed and the last bend is cut and rotated 90 degrees. It seems to work.

Except I have a big leak out of the thermostat area.

It all has to come off again.

And the brake pipe needs to be secured.

Radiator alternator and thermostat all removed, extra clip added to brake pipe.

Seems the leak was most likely just a not tight enough hose clip. but the thermostat needed fitting correctly anyway. Thermostat first then rubber ring.